By quenching parts directly from the hot forge, the instant-impact quenching at the hot shell eliminates the energy wasted by cooling the forging in air and then having to heat the part again (re-Austenitize) for Normalization; then re-heat the forging a third time before a quench and temper to harden the forging.

Since the hot forging leaving the trim dies can be over 2,000F, a very high intensity quenchant flow is needed at the hot part surface shell to eliminate non-uniform film boiling and to set the hardened shell to prevent the part from cracking. A uniform, “instant-impact” of the quenchant over the entire hot part shell sets the part shell’s geometry, prevents part cracking, and provides finer grains for more uniform mechanical properties in the forging.

Since the DFIQ process is consistently uniform, the forger can design the forging trim dies with tighter tolerances and produce parts that are closer to the desired final net shape. Reducing the rough machining costs after forging and providing more consistently uniform mechanical properties in the forged part.

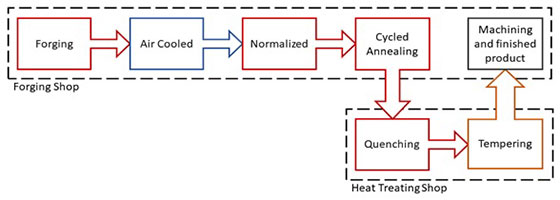

Typical Heat treating process for forged parts

Traditional Quench + Temper Flow Chart: manufacture of a hot forged and hardened part.

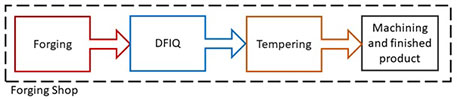

DFIQ™ eliminates multiple steps and wasted energy

Leaner DFIQ™ and Quench2FIT Flow Chart: hardening a forging directly after hot forging eliminates Normalization and a 3rd reheating process.